Screw Piles

Engineered Foundations

That Last

Certified. Precise.

Built for Alberta.

We deliver engineered helical pile foundations that outperform traditional methods in speed, strength, and versatility.

Whether you’re building a new home, supporting a large commercial structure, or stabilizing an existing foundation, our screw piles offer unmatched performance—installed by an Almita™ Certified crew you can trust.

Why Triad?

Almita™ Certified Installers – The gold standard in helical foundation systems.

Engineer Oversight on Every Project – Layout drawings, torque verification, and stamped reports included.

Complete Build Capability – From excavation and gravel prep to slabs, septic, and framing.

Rebate & Loyalty Program – $50 minimum rebate per pile or 5% off additional services for repeat and referral customers.

We Beat Any Price – On directly comparable, certified products.

Serving Rural Alberta – Calgary, Lethbridge, Edmonton, Banff, Medicine Hat, Swift Current SK, and beyond.

Key Benefits

- Rapid Installation: Minimal excavation—installation can be completed in hours, reducing site disturbance and environmental impact.

- Immediate Load Capacity: After reaching specified torque, piles can support design loads instantly, accelerating project timelines.

- Versatility: Suitable for new builds, underpinning, remote sites, and challenging soil conditions (permafrost, high groundwater).

- Adjustability: Height and load-bearing capacity can be fine-tuned on-site; remediation and load adjustments are straightforward.

- Certification: Provide engineer-stamped installation reports and stamped layout drawings for permit approval.

Applications

- HOMES, RTMs, MOBILE HOMES, MODULARS

- UNDERPINING & REMEDIATION of failing foundations in heritage restorations

- Supporting AGRICULTRAL (silos, barns, etc.), SOLAR PANEL RACKS & UTILITY POLE

- REMOTE INDUSTRIAL CAMPS, OIL PATCH FACILITIES where rapid mobilization is critical

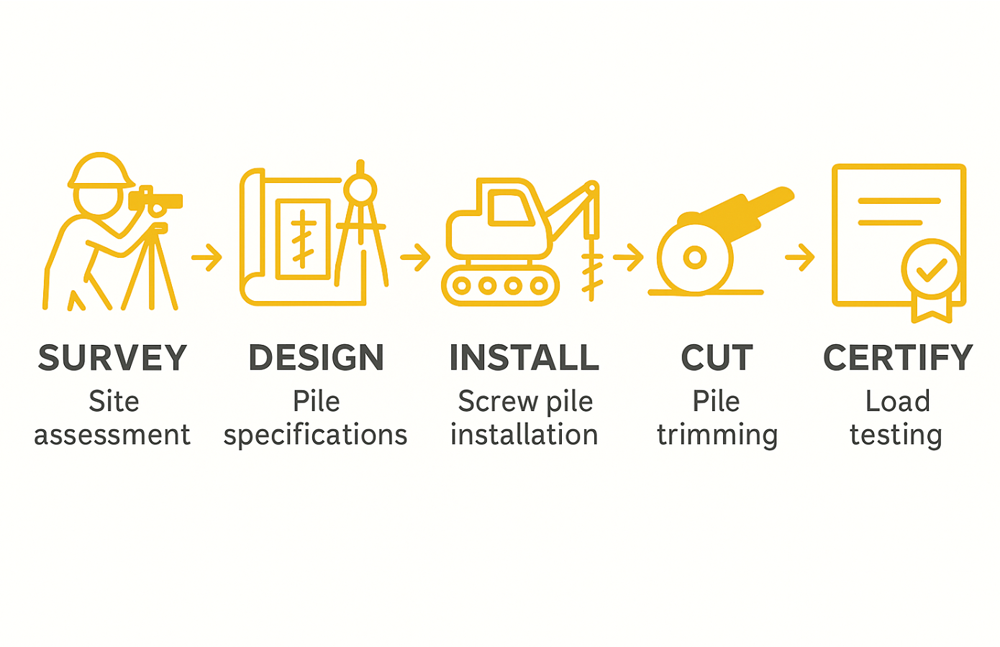

Installation Process

- Site Survey & Layout: Coordinate layout drawings with suppliers; conduct on-site surveying with laser levels.

- Engineered Design: Engineer-certified spacing, helix size, and torque specifications based on soil reports.

- Pile Installation: Deploy hydraulic drive units to torque piles to target resistance values indicating geotechnical capacity.

- Cut & Cap: Trim piles to design elevation; weld pile caps or brackets as per structural requirements.

- Certification: Provide engineer-stamped installation reports and stamped layout drawings for permit approval.

FAQ

What are helical screw piles?

- Helical piles deliver immediate load-bearing capacity, supporting structural loads the moment they’re installed. Unlike concrete or grout methods, they don’t require curing time before use. As a cornerstone of modern construction, helical piles combine rapid deployment with exceptional stability and efficiency.

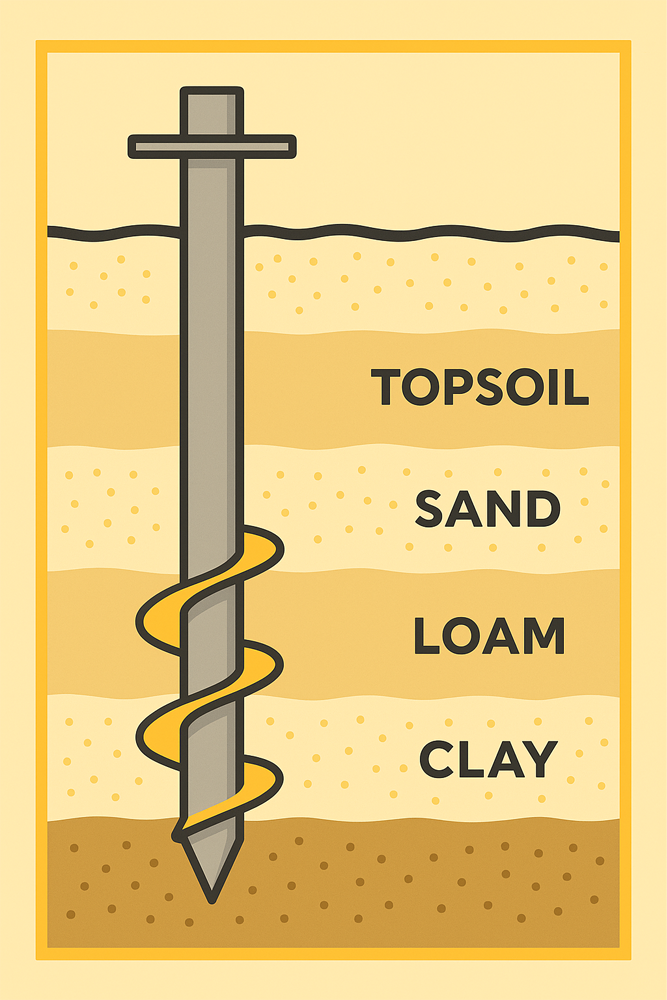

How deep do screw piles need to go?

- Install screw piles below the frost line—typically at least 8 ft (2.4 m)—to achieve the load-bearing capacity and stability your structure requires. Exact depths depend on soil conditions, structure type, and local codes, and may reach 20 ft (6 m) or more when needed.

How long do screw piles last?

- Screw piles—aka helical piles or screw anchors—often exceed 50–75 years of service. Their lifespan hinges on soil conditions, pile materials, and protective coatings, and following proper installation standards helps maximize durability.

How many screw piles do I need?

- The number of screw piles needed depends on the size and type of structure, as well as soil conditions. A general rule of thumb is to space screw piles 8 to 10 feet apart. We are local installers and can provide more specific guidance.

How do you install screw piles?

- Steel shafts topped with helical plates into the ground using a rotating motion—much like screwing into wood—to create a stable, load-bearing foundation. Specialized torque motors or hydraulic drive units rotate the piles while applying downward pressure, making this method ideal for varied soil conditions and tight-access sites.